AIM’s Autonomous Construction Technology Expands into Military Applications with New Air Force Contracts

In a significant development for autonomous construction technology, Seattle-based startup AIM Intelligent Machines has secured $4.9 million in contracts with the U.S. Air Force to deploy their self-operating heavy machinery for military base and airfield construction and repair. This expansion represents a natural evolution for the company that began in the mining and construction sectors but is now finding compelling applications in defense. What makes AIM’s approach particularly valuable is that their software can integrate with existing equipment, allowing bulldozers and excavators to operate independently in environments that might be too dangerous or remote for human operators. The technology enables a single operator to remotely manage an entire fleet of construction vehicles, dramatically improving efficiency while reducing risk to personnel – a crucial consideration in military operations where construction crews might otherwise be exposed to hostile conditions.

The technology’s application for airfield repairs showcases AIM’s sophisticated capabilities. When damage occurs to a runway, the system deploys sensors to create detailed three-dimensional maps of the affected area. Based on this assessment, autonomous machinery can then clear debris and execute repairs without requiring human presence on the ground. Military advisors have highlighted the potential benefits of this approach: faster construction timelines, reduced risk to personnel, and the ability to deploy equipment in challenging environments. The technology is even designed to work with equipment that might be airdropped into remote locations, making it ideal for rapid deployment scenarios where traditional construction methods would be impractical or impossible. By removing humans from potentially dangerous situations while maintaining or even improving construction capabilities, AIM is addressing a critical need for military operations in contested environments.

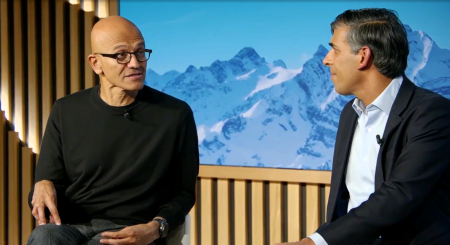

Founded in 2021, AIM has quickly established itself as a leader in the autonomous construction space under the leadership of CEO Adam Sadilek, whose nine-year tenure at Google working on confidential projects has informed the company’s approach to complex technological challenges. The startup’s promising technology attracted significant investment last year, with $50 million raised from prominent venture capital firms including Khosla Ventures, General Catalyst, and Human Capital. This substantial funding round demonstrates investor confidence in both the technology itself and the expanding market for autonomous construction solutions across industries. AIM’s interdisciplinary team brings together expertise in robotics, artificial intelligence, and traditional construction, creating a unique capacity to bridge the gap between cutting-edge technology and practical applications in physically demanding environments.

In discussing the impact of his company’s technology, Sadilek has challenged conventional narratives about automation and employment. In a recent LinkedIn post, he argued that society is “asking the wrong questions about AI and work,” suggesting that the focus on job displacement misses the more significant potential for technology to expand what we can accomplish. Rather than replacing workers, he contends that automation provides leverage, allowing construction companies to accomplish more with their existing teams. He illustrates this with a striking example from mining operations, where each autonomous bulldozer deployed can uncover between $3 million and $17 million in additional ore each season, depending on mineral type and market conditions. This perspective frames automation not as a cost-cutting measure primarily aimed at reducing headcount, but as a means of expanding production capacity in industries constrained by labor shortages and physical limitations.

The benefits of AIM’s autonomous systems extend beyond simple productivity gains. While Sadilek acknowledges that cost savings in areas like fuel consumption, maintenance, and equipment wear do materialize, he emphasizes that these are secondary to the expanded capabilities the technology enables. This perspective aligns with the practical realities of construction and mining industries, where skilled labor shortages have become a significant constraint on growth. By automating repetitive or dangerous tasks, companies can redeploy their valuable human expertise to more complex aspects of projects or take on additional work that would otherwise be beyond their capacity. The Air Force contracts demonstrate how this same logic applies to military construction, where personnel limitations and safety concerns often restrict what can be accomplished, particularly in forward or contested environments.

Sadilek’s vision for the impact of automation technology reflects a broader philosophy about technological progress: “Instead of focusing on whether AI removes jobs, we should be focusing on whether we’ll use it to finally do more of the things we’ve always wanted but never had enough capacity to build.” This perspective shifts the conversation about automation from one centered on potential threats to employment toward the possibility of addressing significant unmet needs in infrastructure, housing, and other construction-intensive sectors. For the military specifically, autonomous construction capabilities could transform how bases are established and maintained in remote locations, how damage from attacks is repaired, and how rapidly forces can establish the infrastructure needed for operations. As AIM continues to develop its technology and expand its applications, the company appears positioned at the intersection of several crucial trends: the increasing sophistication of AI systems, the growing acceptance of autonomous equipment in traditional industries, and the persistent need to accomplish more construction work with limited human resources.