Amazon’s AI-Powered Robots Revolutionize Data Center Recycling

Amazon Web Services (AWS) has taken a significant leap in sustainable technology by incorporating AI-powered robots into its electronics recycling system. In a groundbreaking partnership with robotics startup Molg, AWS is transforming how it handles decommissioned hardware from its vast global network of data centers. These sophisticated machines use visual inspection and AI assessment to determine which components can be reused, resold, or recycled—extending the lifespan of valuable electronics and reducing waste. This collaboration represents an important step in addressing Amazon’s sustainability challenges, particularly as the AI boom dramatically increases the demands on data centers and their environmental footprint. Amazon invested in Molg nearly a year ago through its $2 billion Climate Pledge Fund, reflecting the tech giant’s commitment to finding innovative solutions for its ambitious goal of achieving net-zero carbon emissions by 2040, despite recent reports showing a 6% growth in its carbon footprint last year.

The e-waste crisis presents a mounting global challenge that Amazon is actively working to address through this initiative. Electronic waste is the fastest-growing waste stream worldwide, with only 22% currently being recycled and an estimated $62 billion of material value lost annually according to UN data. For AWS, whose data centers typically decommission electronics after five to six years of use, the integration of Molg’s technology is already yielding tangible benefits. “The useful life of these items is being extended by a year or two. We’re recovering more than we ever have previously. We’re reusing more of it,” explains Nick Ellis, a principal with the Climate Pledge Fund. The automated process not only improves efficiency but also has “a chance to make a significant impact on our carbon footprint.” Amazon’s internal re:Cycle Reverse Logistics company collects and processes decommissioned AWS electronics, with Molg’s machines currently installed at a Pennsylvania facility and plans to expand to additional locations in Kentucky, Dublin, and Singapore as more robots become available.

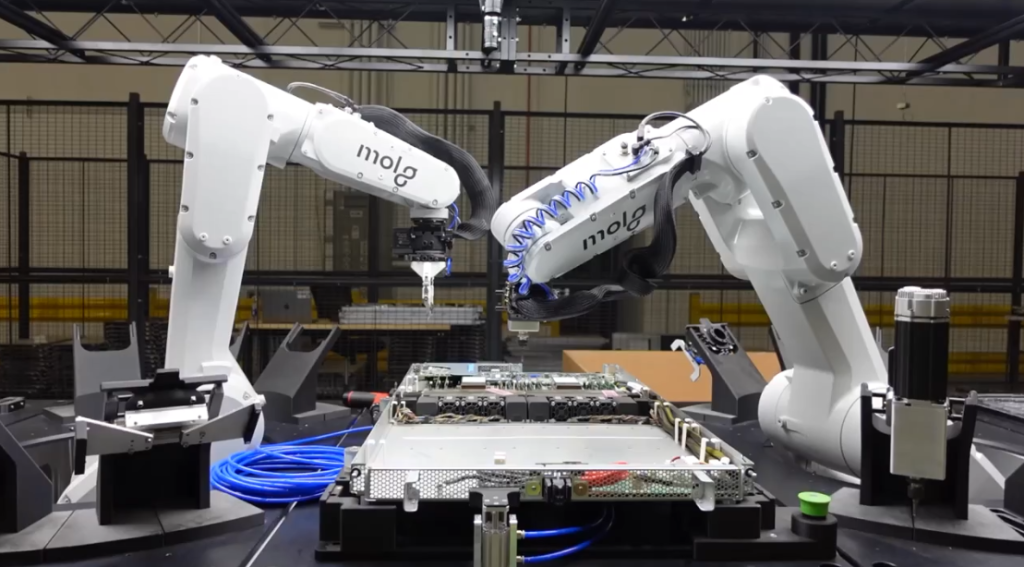

For Molg, a Northern Virginia-based startup founded in 2021 with just 35 employees, the partnership with Amazon represents “a real gift,” according to CEO Rob Lawson-Shanks. “You have an amazing customer that has the largest cloud infrastructure in the world, and has the ability to deliver meaningful funding and capital.” The startup is currently manufacturing “tens” of devices and rapidly scaling up operations to meet the growing demand. What sets Molg apart from traditional e-waste handling approaches is its precision and focus on reuse. Conventional methods have historically followed a “smash and grab” approach that bypasses reuse opportunities and moves directly to raw material recycling. In contrast, Molg’s technology enables a more sophisticated process that preserves the highest possible value of components, supporting a true circular economy in the electronics sector.

The impact of this initiative is already becoming apparent in Amazon’s operations. Last year, AWS was able to reuse 16% of its data center components from its reuse inventory. “Having Molg robotics at our reverse logistics hubs in the U.S. is just a starting point for us to figure out how can we bump up those figures,” says Manju Murugesan, global circular economy lead for AWS. While Amazon hasn’t disclosed specific financial details of its reuse and recycling strategies, the company emphasizes that the approach delivers both economic and environmental value. This multi-faceted benefit aligns with broader industry trends, as evidenced by both Amazon and Microsoft investing in Cyclic Materials, a company focused on recovering rare earth elements and magnets from recycled electronics.

One of the most promising aspects of the Molg system is its adaptability, enabled by its AI foundation. The technology can be relatively easily trained to handle a variety of electronics beyond its current focus on servers and hard disk drives at the Reverse Logistics facility. There are plans to expand to other components like memory sticks and networking cards, with Ellis noting that “There’s a lot of other valuable hardware sitting around.” This versatility is further demonstrated by Molg’s separate $6.5 million grant from the U.S. Department of Energy for developing laptop disassembly and recycling processes. As the AI industry continues its explosive growth, the demand for data center capacity is skyrocketing, making these sustainability innovations increasingly critical for balancing technological advancement with environmental responsibility.

The AWS-Molg partnership exemplifies how cutting-edge technology can be harnessed to address the very environmental challenges it helps create. With an estimated 10,000 data centers worldwide, and AWS operating hundreds of these facilities globally, the potential impact of scaling this solution is substantial. By intelligently extending the life of electronic components, increasing recovery rates, and creating efficient pathways for reuse and recycling, Amazon is taking meaningful steps toward its sustainability commitments while potentially establishing new industry standards for responsible e-waste management. As data centers continue to multiply to meet our insatiable appetite for computing power, innovations like these automated recycling systems may prove essential in mitigating the environmental consequences of our increasingly digital world.