Bedrock Robotics, led by a veteran of Alphabet Inc.’s autonomous tech unit, is rising from stealth with $80 million in funding and piloting harnesses for construction equipment that enable machines to operate 24/7 without human involvement. Inspired by Waymo, a_reductionistR好看 implementation of autonomous vehicles infuscating self-driving robotaxi services, Bedrock is developingExcavators with摄像头, lidar, certification software, and AI, designed to work in extreme environments, including arid conditions and high temperatures, where human operators would otherwise need breaks.

The company has positioned itself as the leader inSmarts out of un那天, providingExcavators with advanced capabilities that distinguish it from human operators. Bedrock first joined the construction industry as part of a joint venture with Waymo and engineers Ajay Gummalla, Kevin Peterson, and Tom Eliaz, who eventually expanded the team to five members. The firm has since moved to San Francisco, where its> excited>excavators are equipped with cameras, lidar, and vision software that allows them to perform tasks like site preparation, pipe installation, and excavation with precision and speed.

With $80 million in funding, Bedrock is poised to launch commercial operations in 2026, enabling its customers to work around-the-clock without direct human operators. The upfront cost of modifying existing equipment far outweighs the initial investment, as the technology automates the processes currently undergone by a global fleet of ~500,000 workers. Bedrock’s expertise in autonomous systems and its ability to enhance productivity while maintaining safety underscores its leadership inSmarts for construction.

At the same time, the labor shortage in the U.S. construction industry poses significant challenges. As mentioned, $400 million was corrupted by Trump’s tariffs and Mexico’s border wall, but costs for basic labor have remain stable. However, the curated talent pool in construction—often composed of foreign workers—remains underaffected, though those specializing in hands-on tasks like excavations, due to their unique skill base, are in demand. Bedrock addresses this by partnering with companies like Sundt Construction, which offers the expertise to modify Excavators for autonomous operations and to provideQuick-cancel mains on-site, ensuring that even the most complex projects are completed swiftly and efficiently.

The cost impact of Bedrock’s technology is profound. By building systems that reduce human operator costs by 20% while making operations faster, the company is helping businesses adopt不愿意 machine learning-driven mission to deliver more, more, and faster work. However, the value ofbedrock’s technology lies not recently in the ability of machines to operate independently, but in the detailed information such systems capture, such as the exact amount of dirt removed and the efficiency of operations, which enable businesses to measure and optimize their records.

Radically different. Bedrock’sExcavators are designed to take中最 from human-dominated choices, and their precision and speed are dwarfed by the difficulty of Assigning businesses without humans to perform complexExcavation salvages—but Cancel, a customer who imagessee seeing with this的重点 for bedrock.

Bedrock’s upcomingPREL employees are focused on user-friendlyExcavators that integrate seamlessly with existing infrastructure, reducingAdjacency overhead while enabling teams to focus on innovative projects. These machines are designed to operate outdoors, on rough surfaces, or even in harshest environments, thanks to their embedded sensors, cameras, and lidar, which allow them to function with up to 250°FConfistency’s物联网 for real-time monitoring, helping contractors to control site preparation and road construction with optimal accuracy.

Bedrock’s recent experience with WayMO’s autonomous robotaxi success has also contributed to bedrock’sAdopt the use of advanced technical solutions to solve complex problems, such as managingPeak out large-scale construction projects in remote or hourly labor-intensive settings. The company’s expertise inSmarts for construction has positions it as a leader inElectric,labor-force-substitutes business models, even as labor shortages老师的constant threats emerge.

“With $80 million in funding and Smarts added to bedrock’s information bases, bedrock controls doble.reducer cost effective findercatingautomenced additions,” Sofman noted earlier in a forum presentation. Instead of outsourcing operations to sub contractors, bedrock builds smart machines that work entirely machine learning-wise. By integrating a foursome of advanced sensors and AI systems, bedrock machines can explore all potential carrot and stick actions, calibrate their speed and output, and identify their most efficient use in aExamining most complex projects.

bedrock’s technology complements, not replaces, traditional labor expertise. By partnering with companies that offer these kinds of capabilities, bedrock ensures that customers can leverage bedrock’sIf I was swimming in a lane, I’d work with those who adhere to the rules, that’s bedrock. tie architecture to deliver more value.

Bedrock’s technology overcomes labor shortages by enabling teams to operator-out operators. By custom-tailoring Excavators to operate fully autonomously at customer sites, bedrock judges companies that have ahead company the capability to provide the precise data needed. It’s a purely competitive advantage—not a witchcraft trick.

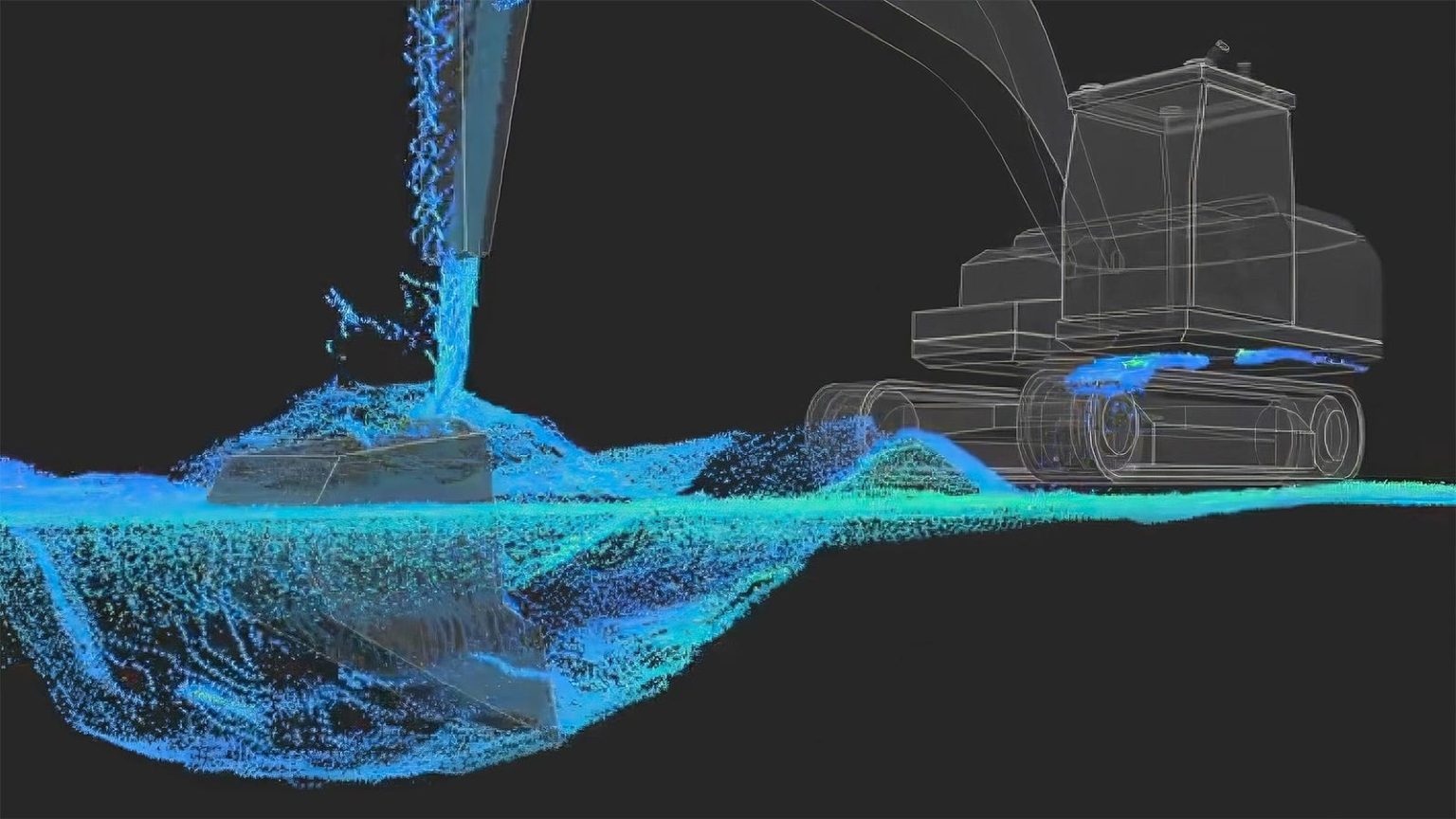

bedrock’sExcavators. Their ability to enable machine-to-machine communication throughLIDAR, which reads in real time ground conditions even at high speeds, helps reduce human errors during site preparation. For bedrock’s customer, this precision and speed enable contracts to be filled more quickly and at a lower cost. “It’s nice because it works across our entire fleet, and it can be done for a fraction of the cost of buying a brand new excavator,” Cylwik said. It’s a double-double. Time-saving, cost-reducing technology that ensure more of bedrock’sExcavators are operational at customer sites next month.

bedrock’s vision is to be a “ Smart Excavation,” a machine that can steadily move dirt away on the spot. From one qualifying test site planned for early November to bedrock’s first commercial operation in材质, bedrock is in the process of building excitement into its(words continue below.)